The Role of Maxcore Industries in the Automotive Core Supply Chain

The automotive industry is a complex web of interconnected parts and processes, and at the heart of it lies the critical role of core suppliers. These suppliers are the lifeblood of remanufacturers, providing them with the essential components needed to breathe new life into automotive parts. Maxcore Industries, a full-line core supplier, stands at the forefront of this ecosystem, playing a pivotal role in the automotive core supply chain. Let’s explore Maxcore Industries' integral function and how their innovative approach is transforming the industry.

A Full-Line Core Supplier's Commitment to Excellence

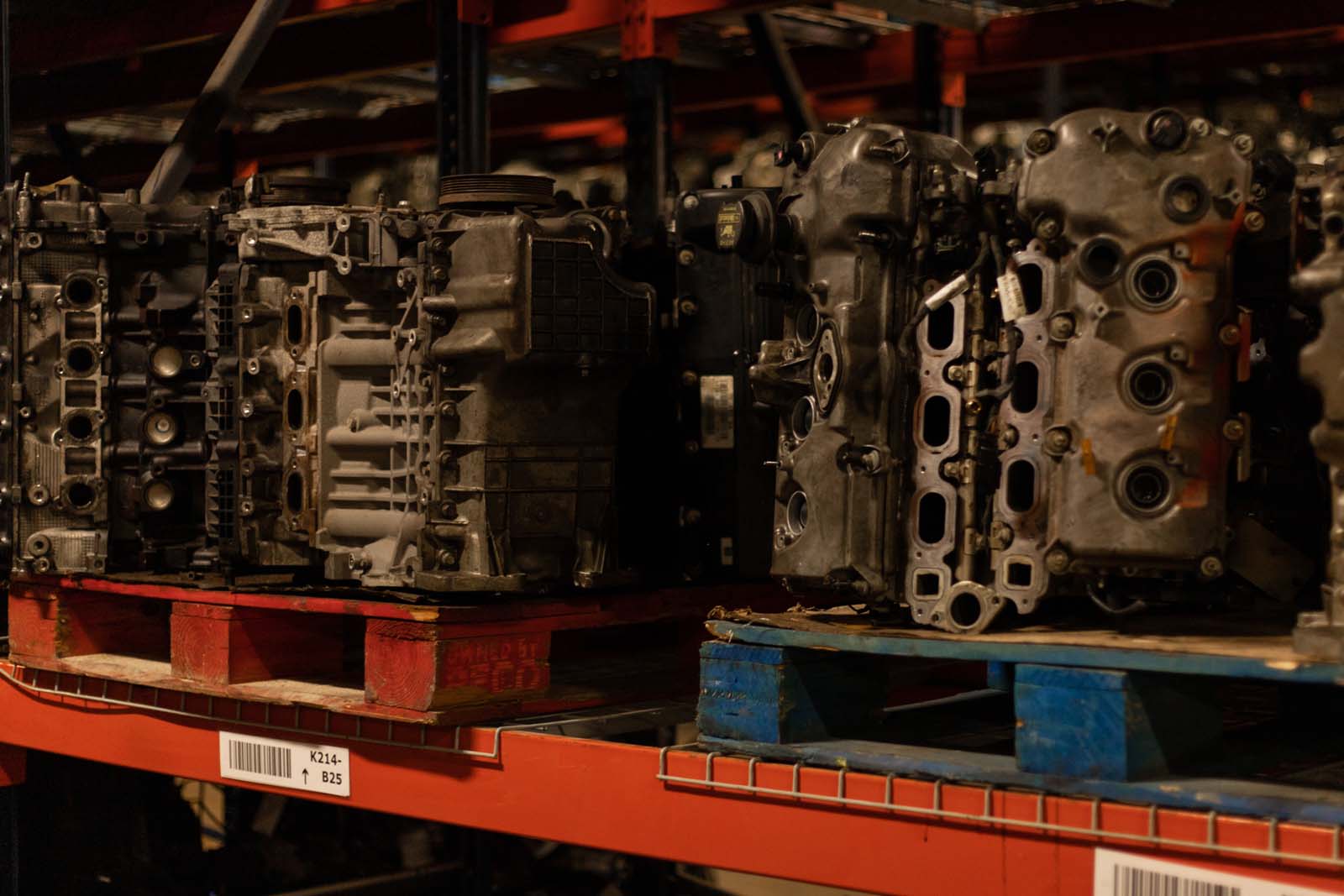

As a full-line core supplier, Maxcore Industries serves as a comprehensive source for a wide range of automotive components, from engines and transmissions to complex electronics. The term "full-line core supplier" encapsulates their role in providing remanufacturers with the essential parts required to rebuild and refurbish vehicles.

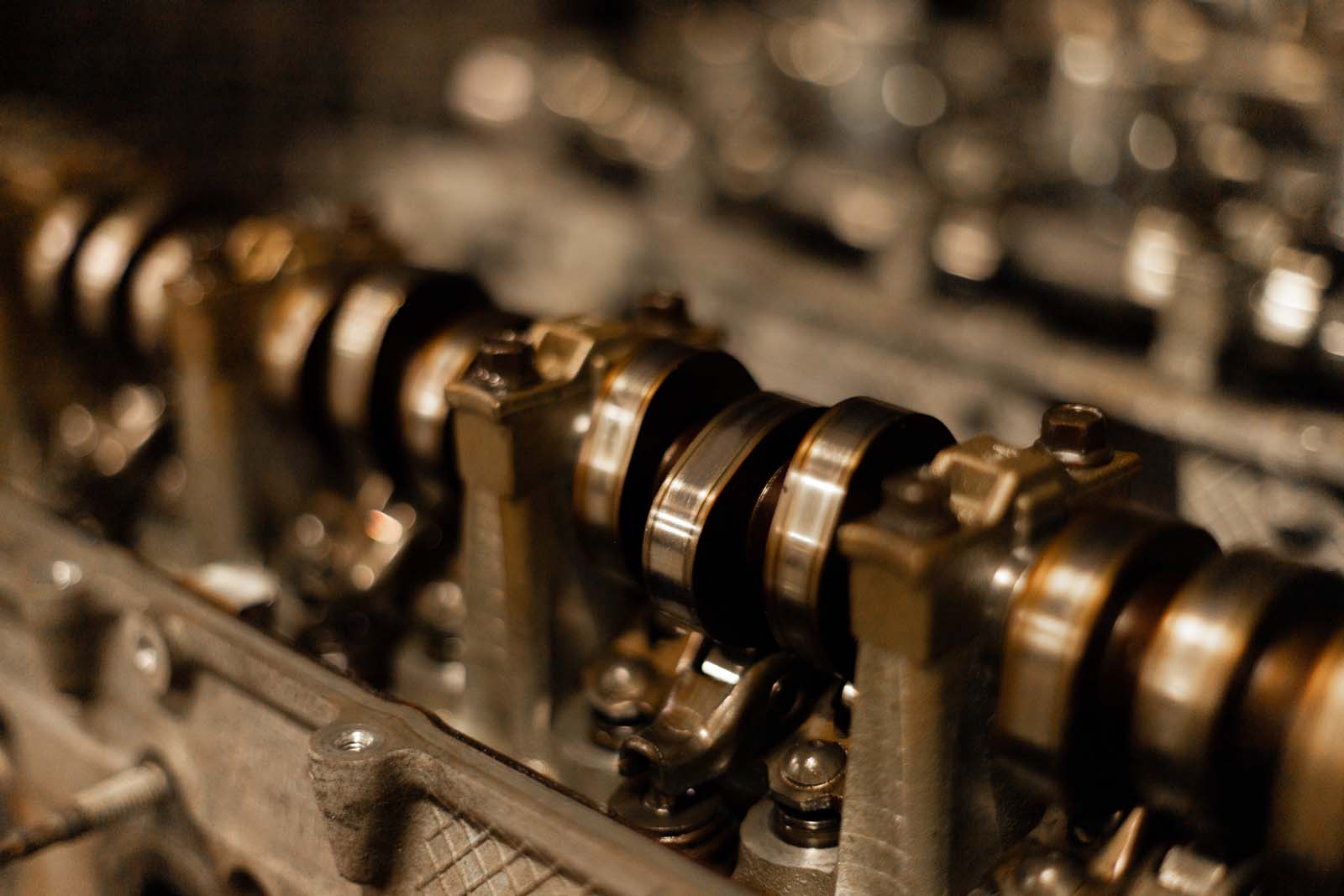

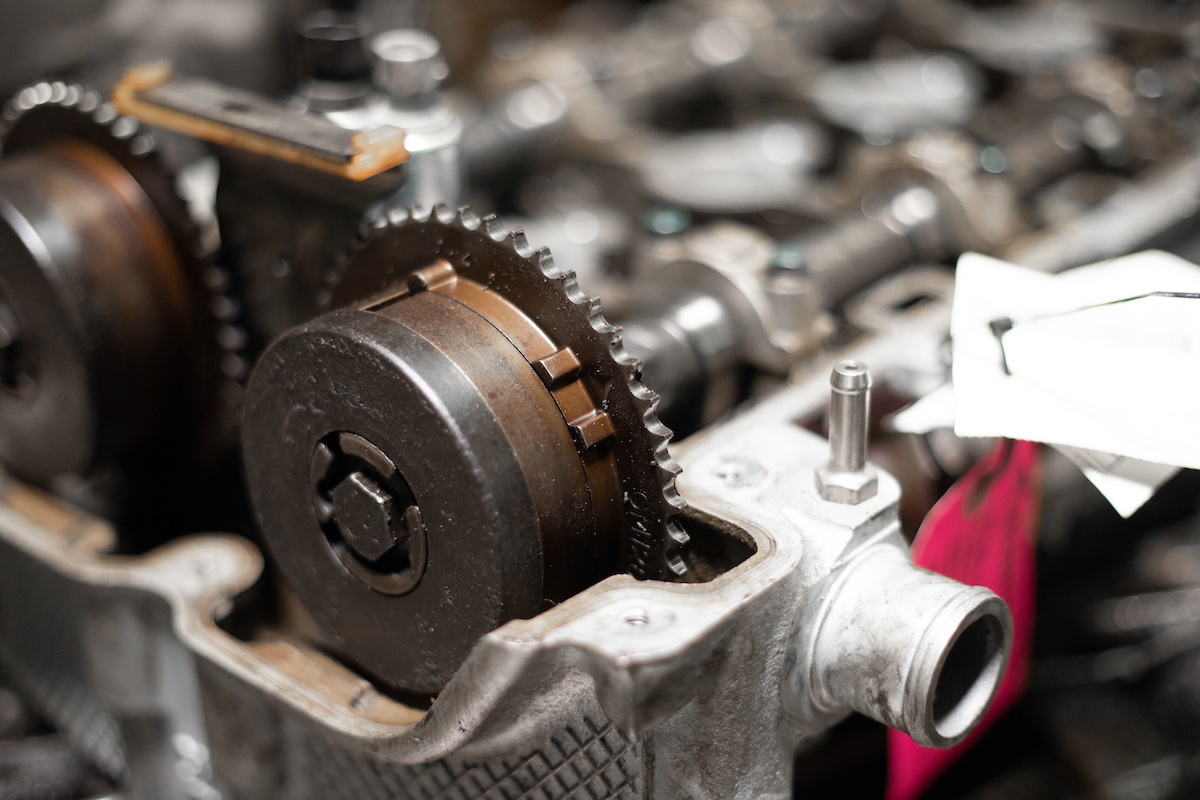

The core supplier role is pivotal in ensuring the success of remanufacturing, a process that not only saves money for consumers but also significantly reduces the environmental impact of the automotive industry. The process starts with the careful selection of core components. For example, when a vehicle reaches the end of its life or is involved in an accident, its components, such as the engine or transmission, may still hold value. However, these components need to be rebuilt, often referred to as remanufactured, to meet or exceed original equipment manufacturer (OEM) standards. This is where core suppliers like Maxcore Industries come into play.

Maxcore's full-line offering is a testament to their commitment to serving the diverse needs of remanufacturers. Their product catalog spans a multitude of components, ensuring that remanufacturers can find the cores they need without the hassle of dealing with multiple suppliers. From the humble AC compressors to the intricate wiper motors, Maxcore Industries has assembled a vast inventory of core components that are vital to the remanufacturing process.

Efficiency Through a VIN-Based Program

One of Maxcore Industries' standout features is their innovative VIN-based program, which sets them apart in the automotive core supply chain. This program streamlines the connection between remanufacturers and a vast network of automotive recyclers. The VIN-based program operates on the idea of connecting the right core with the right remanufacturer, making the process more efficient and targeted.

Every vehicle has a Vehicle Identification Number (VIN), a unique code that contains information about the vehicle's make, model, and year. Maxcore Industries leverages this information to match remanufacturers with the specific cores they need. This precision ensures that remanufacturers receive exactly what they require for their projects, avoiding unnecessary waste and inefficiency. Through the VIN-based program, Maxcore Industries connects remanufacturers to thousands of automotive recyclers, creating a bridge that benefits everyone in the supply chain.

The program operates in a way that benefits remanufacturers, automotive recyclers, and the environment. It minimizes the chances of acquiring incorrect or unsuitable cores, saving both time and resources. Moreover, the efficient use of cores is a crucial step toward sustainability, as it reduces the environmental impact associated with the creation of new parts. Maxcore's commitment to this level of efficiency echoes their dedication to reducing waste and improving the remanufacturing process for the entire industry.

MAXCORE

Maxcore Industries, as a full-line core supplier, plays an essential role in the automotive core supply chain.

Trustworthy Core Supplier for Remanufacturers

In the world of core suppliers, trust is paramount. Remanufacturers rely on core suppliers to provide them with high-quality, rebuildable components that can meet or exceed OEM standards. Maxcore Industries understands the importance of this trust and works diligently to maintain it.

As a core supplier, Maxcore places a strong emphasis on delivering components that remanufacturers can trust. Each core is carefully assessed to determine its condition and rebuildability. Skilled technicians evaluate the core, ensuring that it meets the stringent quality standards required for successful remanufacturing. This process is vital because it ensures that remanufacturers receive cores that are not only reliable but also capable of performing to the high standards demanded by consumers.

The reputation of a core supplier hinges on their ability to provide reliable cores, and Maxcore Industries has established itself as a trustworthy partner for remanufacturers. The trust that remanufacturers place in Maxcore stems from their commitment to quality assurance and their role in bridging the gap between the recycling and remanufacturing sectors.

Maxcore Industries, as a full-line core supplier, plays an essential role in the automotive core supply chain. Their commitment to excellence, innovative VIN-based program, and reputation as a trustworthy core supplier make them a pillar of support for remanufacturers. By providing a comprehensive range of automotive components, streamlining core acquisition through their VIN-based program, and upholding strict quality standards, Maxcore Industries is redefining the core supplier landscape and contributing significantly to the sustainability of the automotive industry. Their journey to connect remanufacturers with reliable cores displays their dedication to preserving resources, saving consumers money, and reducing the environmental impact of the automotive industry. Maxcore Industries, as a core supplier, is at the forefront of positive change, contributing to a greener and more efficient future in the world of automotive remanufacturing.